Projects and fascinations

To relax from building things full-time … I build other things, part-time. Just for fun, always from scratch, and mostly solo - these are a few examples made in my home workshop, college shops, or Humanmade in SF:

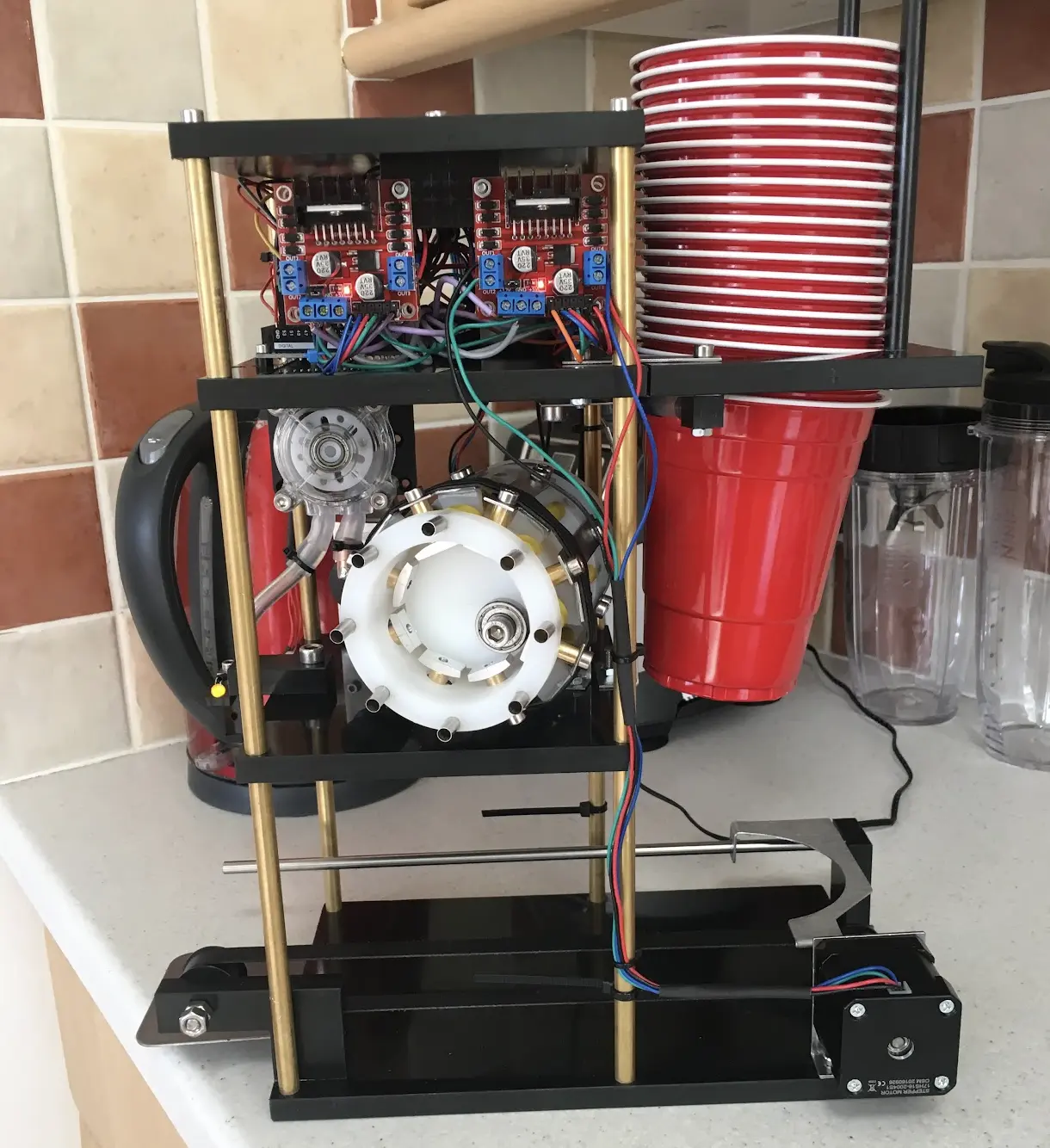

Bean-to-bar small batch chocolate maker - 2025

This one is a WIP right now, but it already does exactly what you think. I spent a great deal of time thinking about how to combine the challenges of grinding, conching, and tempering into a single, fairly simple architecture that can replace multiple devices and finicky processes, all at a scale suitable for a chocolate-obsessed individual like me. So much to say about this one - definitely ask me more!

Media console/sound system - 2025

American Cherry with Rooibos (my favourite tea) stained panels. This console hides a full sound system within and uses a joining system that neatly hides where the actual connections exist. The hand-carved “fingerprint” texture on top contrasts the other machine-created forms.

“Jelly Lamp” - 2025

A tensegrity structure using the power cord itself gives the shades of these lamps a slightly wobble when touched, which is not what the machined Richlite construction suggests will happen. I liked it so much I ended up making three of them.

Dining table - 2025

Black Walnut and Slate Richlite. When I couldn't find a compact dining table for my very compact apartment, this was born.

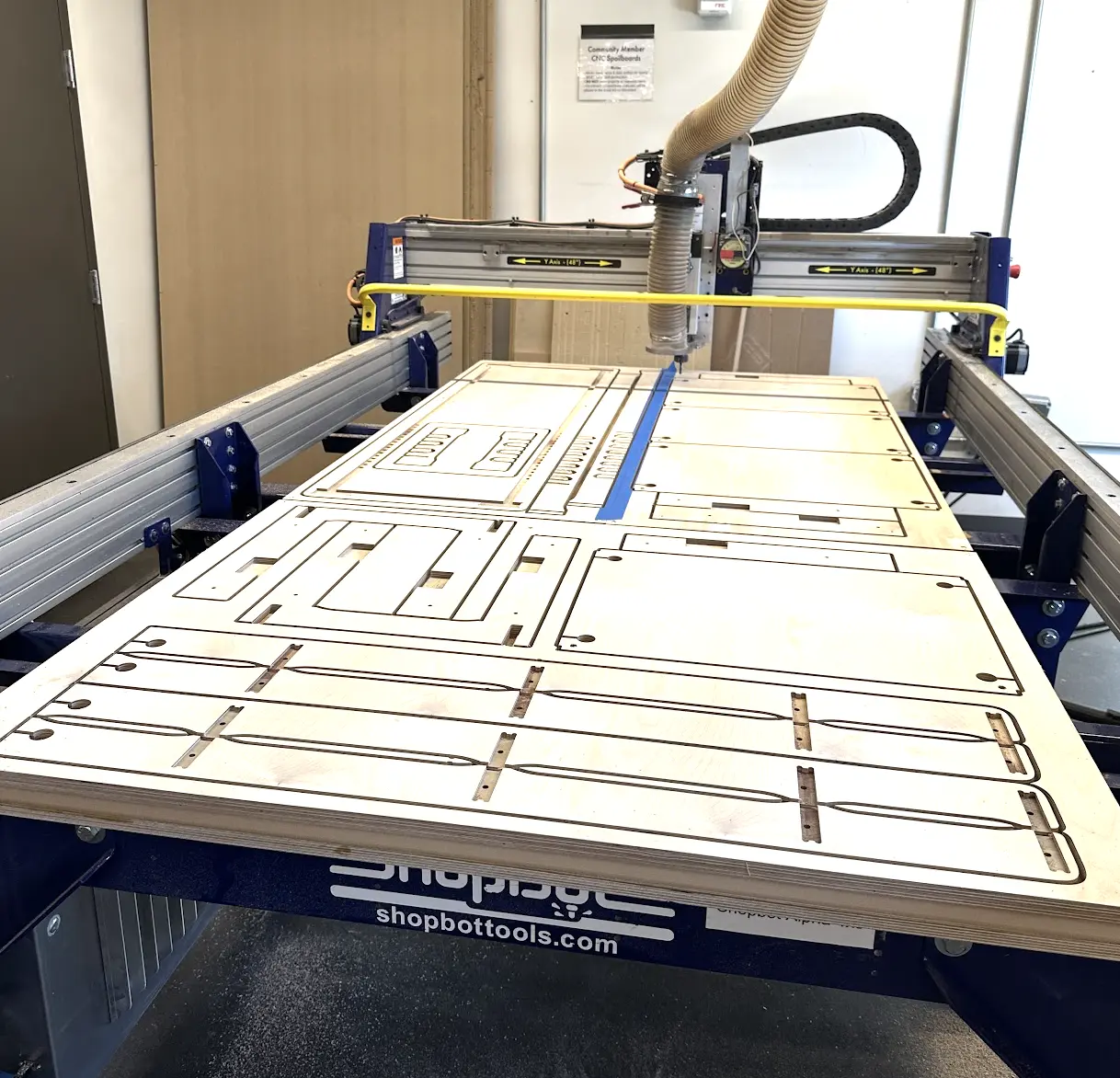

Bookcase-bench - 2025

Birch ply and old rope. I designed this robust piece to neatly fill a standard sheet of plywood and be 100% machinable on a CNC router.

Magnet-reaction Anglepoise lamp - 2023

Fiddling with some magnets one day, I realised they could be configured to create specific shear and friction force profiles when slid apart, which is exactly what makes an Anglepoise style arm work. I built 2D magnetic field simulations MATLAB to find the perfect parameters and packaged everything into an (almost) impossibly slender machined Richlite structure where no springs are used at all.

Espresso machine - 2021

Borrowing just the boiler-grouphead of a Saeco machine, I built a new enclosure and ditched all the analog electronics for a custom made 1200W digital controller and touchscreen UI. This machine has made well over 1000 shots.

Automatic bartender robot - 2018

The essential college project. This neat little machine combines all sorts of novel mechanisms, sensors, and automations to make any drink from 8 different inputs. I wrote a little bluetooth enabled android UI app, and it can even flush itself clean.

GT Off-Road - 2016-2020

Worth mentioning again here since this was such a significant part of my college experience, often beating coursework for time consumption. I held positions from manufacturing lead, to DAQ lead, to chief engineer.

Electric go-kart - 2017

Designed and built in a winter break sprint, 20mph never felt so fast. Welded steel frame, lead-acid batteries, RWD, even regen braking. That is indeed a chair from a school classroom.

Hybrid rocket motors - 2017

It was actually the DAQ and CFD opportunities that got me most interested in making these. All manually machined, arduino controlled (from a safe distance), and fired successfully a number of times, these were the loudest fun I've had.

Honorable mentions

Automatic fish feeder device, active toolpost for lathe, bicycle mounted steam engine, more furniture and lamps, innumerable 3D printed spare parts and other solutions…

Food!

I cook with gusto every day; I'm a committed foodie and a close scene/industry follower.